Amagama angukhiye: I-Fanchi-tech checkweigher, ukuhlolwa komkhiqizo, ukugcwaliswa kancane, ukugcwaliswa ngokweqile, ukuphiwa, izigcwalisi ze-auger volumetric, izimpushana

Ukuqinisekisa ukuthi isisindo somkhiqizo wokugcina singaphakathi kwamazinga amaminithi/ubukhulu obamukelekayo kungenye yezinjongo ezibalulekile zokukhiqiza ukudla, iziphuzo, ezenza imithi kanye nezinkampani ezihlobene.Ukugcwaliswa ngokweqile kubonisa ukuthi inkampani inikela ngomkhiqizo onganxeshezelwa ngawo;Ukungagcwalisi kahle kusho ukuthi izimfuneko zomthetho azihlangabezwana ezingase ziholele ekubuyiselweni emuva kanye nesinyathelo sokulawula.

Emashumini amaningi eminyaka, ama-checkweighers abekwe emgqeni wokukhiqiza ngemuva kokusebenza kokugcwalisa/ukubeka uphawu.Lawa mayunithi anikeze amaphrosesa ulwazi olubalulekile lokuthi imikhiqizo iyahlangabezana yini nemibandela yesisindo esimisiwe.Nokho, imigqa yokukhiqiza iye yaba yinkimbinkimbi kakhulu eminyakeni yamuva.Ikhono lokunikeza idatha ebalulekile emuva kusigcwalisi ngesikhathi sangempela kanye/noma kuzilawuli ze-logicable logic (PLCs) ezisebenzisa imigqa yokukhiqiza, lenze ama-checkweighers abaluleke kakhulu.Inhloso wukukwazi ukwenza izinguquko zokugcwalisa “ngokuphazima kweso” ukuze isisindo sephakheji egcwalisiwe sihlale sisebangeni futhi kuqedwe ukuphiwa okungahlosiwe kokuqukethwe komkhiqizo onenani eliphezulu.

Leli khono lizuzisa kakhulu izigcwali ze-volumetric auger ezivame ukusetshenziselwa imikhiqizo eyimpuphu.Izibonelo zifaka:

Ukudla:Ufulawa, ingxube yekhekhe, ikhofi eligayiwe, i-gelatin Isiphuzo: Ingxube yesiphuzo esiyimpusha, igxilaImithi/imithi yokudla okunomsoco:Izidakamizwa eziwumpushana, izimpushana zamaprotheni, izithasiselo zokudla okunomsocoUkunakekela komuntu siqu:Impushana yengane/i-talcum, inhlanzeko yabesifazane, ukunakekelwa kwezinyawo Imboni/yasekhaya: I-cartridge powder powder, ukugxila kwamakhemikhali

Incazelo: i-volumetric auger filler

I-volumetric auger filler iyindlela yokugcwalisa ekala umkhiqizo, ngokuvamile okuyimpushana noma okuqinile okugeleza mahhala, kusetshenziswa i-auger ezungeziswa ngenani elinqunywe kusengaphambili lokuphenduka ku-conical hopper ukukhipha umthamo odingekayo womkhiqizo.Inzuzo eyinhloko yale mishini yikhono labo lokulawula uthuli ngesikhathi sokusebenza kokugcwalisa futhi ngakho-ke isetshenziselwa kakhulu ama-powders nezinsimbi ezinothuli ezigeleza mahhala.Ukuze kunxeshezelwe izinguquko ekumineni kwenqwaba yomkhiqizo, izigcwalisi ze-auger zivame ukusetshenziswa ngokuhambisana nensimbi yokukala njenge-checkweigher.Izigcwalisi zalolu hlobo zifanelekile ukugcwalisa imikhiqizo kokubili ngesivinini esiphansi nesiphakathi.

Izihlungi ze-Volumetric auger: izimfanelo zokusebenza

Izici zokuminyana zemikhiqizo eyimpuphu egcwaliswe izigcwalisi ze-volumetric zithintwa ukuthi kungakanani ku-fill hopper.Isibonelo, uma i-hopper igcwaliswa eduze nomthamo, umkhiqizo ongezansi uba minyene kakhulu.(Imvelo yayo engasindi, izinhlayiyana ezincane ibangela ukuthi ihlangane.) Lokhu kusho ukuthi ivolumu yokugcwalisa ephansi izokwanelisa imfuneko yesisindo esiphrintiwe.Njengoba okuqukethwe kwe-hopper kudla (ngesikulufu se-auger/isikhathi) futhi kugcwalise isiqukathi, umkhiqizo osele awuminyene kancane, udinga ukugcwaliswa okukhulu ukuze ukwanelise izimfuneko zesisindo esiqondiwe.

Kulesi simo, kungase kube khona ukuhluka okukhulu phakathi kwamahora phakathi kokugcwalisa nokungaphansi.Uma lezi zingabanjwa esigabeni se-checkweigher, iphesenti eliphezulu kunalena elamukelekayo lokwenziwa komkhiqizo liyanqatshwa futhi ngokuvamile liyabhujiswa.Akukhona nje kuphela ukuthi umkhiqizo unomthelela, kodwa nezindleko zokupakisha nezabasebenzi nazo ziphezulu.

Indlela esebenza kahle kakhulu ukusebenzisa ikhono lempendulo ye-checkweigher ukutshela isigcwalisi ngesikhathi sangempela lapho kudingeka kwenziwe ukulungiswa.

Ngaphandle kwemikhiqizo eyimpuphu

Ikhono le-checkweigher lokunikeza impendulo kusigcwali kanye/noma kuma-PLC asebenzisa imigqa yokukhiqiza alikhawulelwe emikhiqizweni eyimpuphu.Ibalulekile futhi kunoma yimuphi umkhiqizo lapho izinga lokugcwalisa noma ivolumu ingalungiswa “ngokuhamba kwesikhathi.”Kunezindlela eziningi zokuhlinzeka ngolwazi lwempendulo.Enye indlela ukuhlinzeka ngolwazi lwesisindo ngesisekelo sephakheji ngalinye.I-PLC yomugqa wokukhiqiza ingathatha leyo datha futhi iqalise noma yisiphi isenzo esidingekayo ukuze kugcinwe ukugcwaliswa ngaphakathi kwebanga elifanele.

Lapho leli khono libaluleka kakhulu kumcubunguli wokudla kusekunciphiseni ukupha okungahlosiwe.Izibonelo zihlanganisa ama-slurries anenani eliphakeme kanye nezinhlayiya esobho, amasoso, ama-pizza nokunye ukudla okuphekiwe.Ngokungeziwe ekugcwaliseni i-auger (okubhekiselwe kuyo esigabeni semikhiqizo eyimpuphu), izigcwalisi zephistoni nezidlidlizayo zingazuza kudatha yempendulo.

Nansi indlela esebenza ngayo

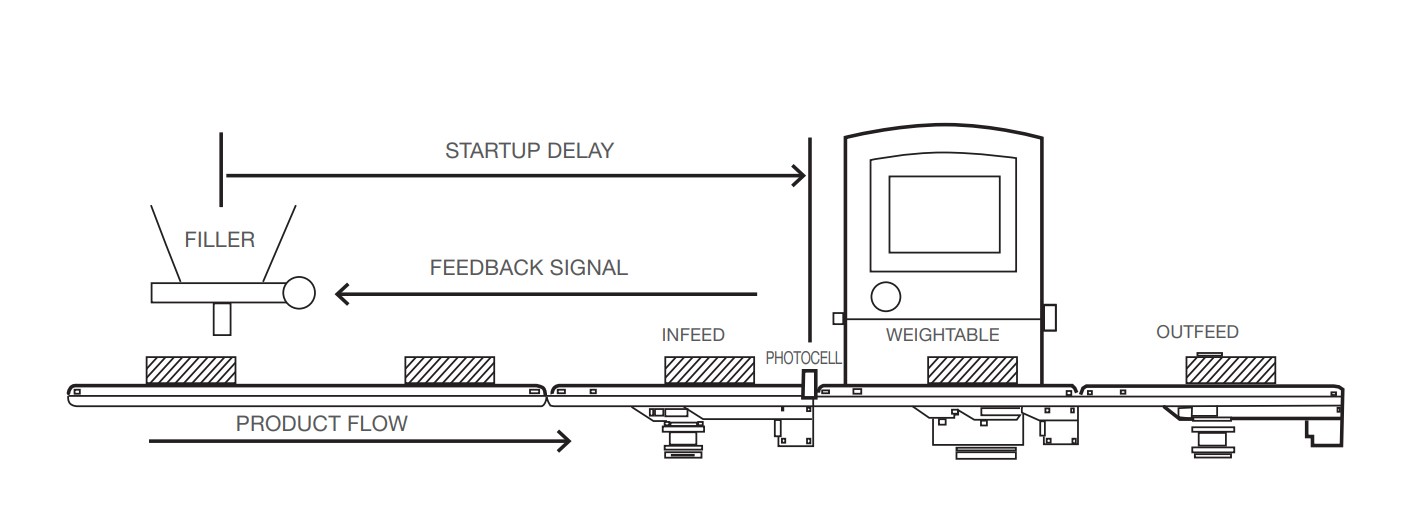

Ngesikhathi sokukhiqiza, isisindo esijwayelekile silinganiswa ngenani lemikhiqizo enqunywe kusengaphambili.Ukuchezuka kwesisindo esiqondisiwe kubalwa futhi kuthathwe isinyathelo lapho kudingeka ngesignali yokulungiswa kwempendulo ukuya kusigcwalisi esivela kusilinganisi sokuhlola.Ukubambezeleka kusetshenziselwa ukugwema ukulungiswa ngokweqile lapho isigcwalisi sisesigabeni sokuqala noma ngemva koshintsho lomkhiqizo.

Umphathi weplanti angasebenzisa isofthiwe ye-checkweigher ozikhethela yona ukuze abuyisele idatha kusihlungi.Okunye, idatha ye-checkweigher ingathunyelwa kusofthiwe yokukhiqiza eyinkimbinkimbi okungenzeka iphrosesa iyisebenzisela ukuphatha amapharamitha wokukhiqiza.

Yisiphi isikhathi esikahle sokwengeza ukusebenza kwempendulo?

Abaphathi bezitshalo nezinkampani bahlale bebuka izindleko ezinkulu futhi babala ukukhokhelwa.Ukwengeza lolu hlobo lomsebenzi kumsebenzi wokukhiqiza kungathola imbuyiselo ngesikhathi esifanele, ngenxa yezinzuzo zokonga ezishiwo ngaphambilini.

Isikhathi esifanelekile sokubuyekeza izinketho kulapho ulayini omusha wokukhiqiza uklanywa noma lapho ama-filler nama-checkweighers kubuyekezwa ukusebenza kahle.Kungase futhi kufaneleke lapho kwenziwa isinqumo sokuthi kunephesenti eliphezulu lemfucuza yesithako ebizayo ngenxa yokugcwala ngokweqile, noma uma ukugcwaliswa kancane kancane kubeka inkampani engozini yesenzo sokulawula noma izikhalazo zabathengi.

Ukucatshangelwa okwengeziwe kokuhlola isilinganiso esiphezulu

Kubalulekile futhi ukuthi ungazinaki ezinye iziqondiso eziyisisekelo zokusebenza okuphezulu kwesikali sikashekhi.Lokhu kubandakanya:

• Thola i-checkweigher eduze nesigcwalisi

• Gcina isikali sakho sisesimweni esihle

• Qiniseka ukuthi isignali yempendulo ihlanganiswe kahle nesigcwalisi

• Gcina isethulo esifanele (isikhala, ukuphakama) komkhiqizo kumlinganisi wokuhlola

Funda kabanzi

Inzuzo yezezimali yenkampani ngayinye ingahluka kakhulu kuye ngenani nezindleko zokunikezwa komkhiqizo ezingancishiswa kakhulu ngedatha yesikhathi sangempela ebalulekile.

If you would like to get more information on how we can assist you with your product inspection requirements, please contact us at fanchitech@outlook.com.

Isikhathi sokuthumela: Jun-14-2022