Amagama aphambili: I-Fanchi-tech checkweigher, ukuhlolwa kwemveliso, ukungagcwalisi, ukuzaliswa, ukuphiwa, izihluzi ze-auger volumetric, umgubo

Ukuqinisekisa ukuba ubunzima bokugqibela bemveliso buphakathi komlinganiselo owamkelekileyo wemin/max yenye yeenjongo ezibalulekileyo zokwenziwa kokutya, iziselo, amayeza kunye neenkampani ezinxulumeneyo.Ukugcwalisa umqondiso wokuba inkampani inikezela ngemveliso engahlawulwayo;ukungagcwaliswa kakuhle kuthetha ukuba iimfuno zomthetho azifikelelwa nto leyo enokukhokelela ekukhunjweni nasekuthatheni amanyathelo olawulo.

Kwiminyaka emininzi, i-checkweighers ibekwe kumgca wemveliso emva kokuzaliswa / ukutywinwa komsebenzi.Ezi yunithi zinike iiprosesa ulwazi oluxabisekileyo malunga nokuba ngaba iimveliso ziyahlangabezana neenqobo zobunzima obumiselweyo.Nangona kunjalo, imigca yemveliso iye yaphucuka ngakumbi kwiminyaka yakutshanje.Ukukwazi ukubonelela ngedatha ebalulekileyo kwi-filler ngexesha langempela kunye / okanye kwi-programmable logic controllers (PLCs) eqhuba imigca yokuvelisa, yenze ukuba i-checkweighers ibaluleke ngakumbi.Injongo kukukwazi ukwenza uhlengahlengiso lokuzalisa "kwi-fly" ukwenzela ukuba ubunzima bepakethe egcweleyo buhlala buhlala kuluhlu kunye nokunikezelwa okungalindelekanga komxholo wemveliso yexabiso eliphezulu kupheliswa.

Obu buchule buluncedo ngakumbi kwizihluzi ze-auger zevolumetric ezidla ngokusetyenziselwa iimveliso zomgubo.Imizekelo ibandakanya:

Ukutya:Umgubo, umxube wekeyiki, ikofu egayiweyo, igelatin Isiselo: Imixube yesiselo esigayiweyo, sigxininiseAmachiza/ezondlo:Iziyobisi ezinomgubo, iiprotheyini zomgubo, izongezo zesondloUkhathalelo lomntu:Umntwana/umgubo we-talcum, ucoceko lwabasetyhini, ukhathalelo lweenyawo kwimizi-mveliso/usapho: Umgubo wekhatriji yesishicileli, ugxininiso lwekhemikhali

Inkcazo: i-volumetric auger filler

I-volumetric auger filler yindlela yokuzalisa elinganisa imveliso, ngokuqhelekileyo umgubo okanye izinto eziqinileyo ezihamba ngokukhululekileyo, zisebenzisa i-auger ejikeleziswa kwinani eliqingiweyo leenguqu kwi-conical hopper ukukhupha umthamo ofunekayo wemveliso.Inzuzo ephambili yale mishini kukukwazi ukulawula uthuli ngexesha lokusebenza kokuzaliswa kwaye ngoko ke isetyenziswe ngokubanzi kwi-powders kunye nothuli olukhululekile.Ukuhlawulela utshintsho kwi-bulk density yemveliso, i-auger fillers isetyenziswa rhoqo kunye nesixhobo sokulinganisa njenge-checkweigher.Abafakeli bolu hlobo bafanelekile ukuzalisa iimveliso kwisantya esiphantsi kunye nesiphakathi.

Iifayili ze-Volumetric auger: iimpawu zokusebenza

Iimpawu zoxinaniso lweemveliso zomgubo ezizaliswe zizihlunu zevolumetric zichaphazeleka ukuba zininzi kangakanani kwi-fill hopper.Ngokomzekelo, ukuba i-hopper izaliswe kufuphi nomthamo, imveliso ephantsi iya kuba nzima ngakumbi.Njengoko imixholo ye-hopper iphuma (nge-auger/i-time screw) kwaye ugcwalise isikhongozeli, imveliso eshiyekileyo ayixinene kangako, ifuna ukuzaliswa okukhulu ukwanelisa iimfuno zobunzima obujoliswe kuko.

Kule meko, kunokubakho umahluko obonakalayo phakathi kweeyure phakathi kokungaphezulu kunye nokuzaliswa ngaphantsi.Ukuba ezi azibanjwanga kwinqanaba lokutshekisha, ipesenti ephezulu kuneyamkelekileyo yokukhutshwa kwemveliso iyaliwa kwaye isoloko itshatyalaliswa.Imveliso yemveliso ayichaphazelekanga kuphela, kodwa izinto zokupakisha kunye neendleko zabasebenzi nazo ziphezulu.

Eyona ndlela isebenzayo kukusebenzisa amandla engxelo ye-checkweigher ukuxelela isigcwalisi ngexesha lokwenyani xa uhlengahlengiso kufuneka lwenziwe.

Ngaphandle kweemveliso zomgubo

Ukukwazi kwe-checkweigher ukubonelela ngengxelo kwisihluzi kunye / okanye kwii-PLCs eziqhuba imigca yokuvelisa ayiphelelanga kwiimveliso zomgubo.Ikwabalulekile kuyo nayiphi na imveliso apho ireyithi yokuzaliswa okanye umthamo unokuhlengahlengiswa “ngokubhabha.” Kukho iindlela ezininzi zokubonelela ngengxelo yengxelo.Enye indlela kukubonelela ngolwazi lobunzima kwi-package nganye.I-PLC yomgca wemveliso inokuthatha loo datha kwaye iqalise nayiphi na into efunekayo ukugcina ukuzaliswa ngaphakathi koluhlu olufanelekileyo.

Apho obu buchule buba buxabiseke ngakumbi kwiprosesa yokutya kukunciphisa ukuphiwa okungacetywanga.Imizekelo ibandakanya i-slurries enexabiso eliphezulu kunye ne-particulates kwiisuphu, iisosi, iipizza kunye nokunye ukutya okulungisiweyo.Ukongeza kokuzaliswa kwe-auger (ekukhankanyiweyo kwicandelo leemveliso zomgubo), i-piston kunye ne-vibratory fillers nazo zinokuzuza kwidatha yempendulo.

Nantsi indlela esebenza ngayo

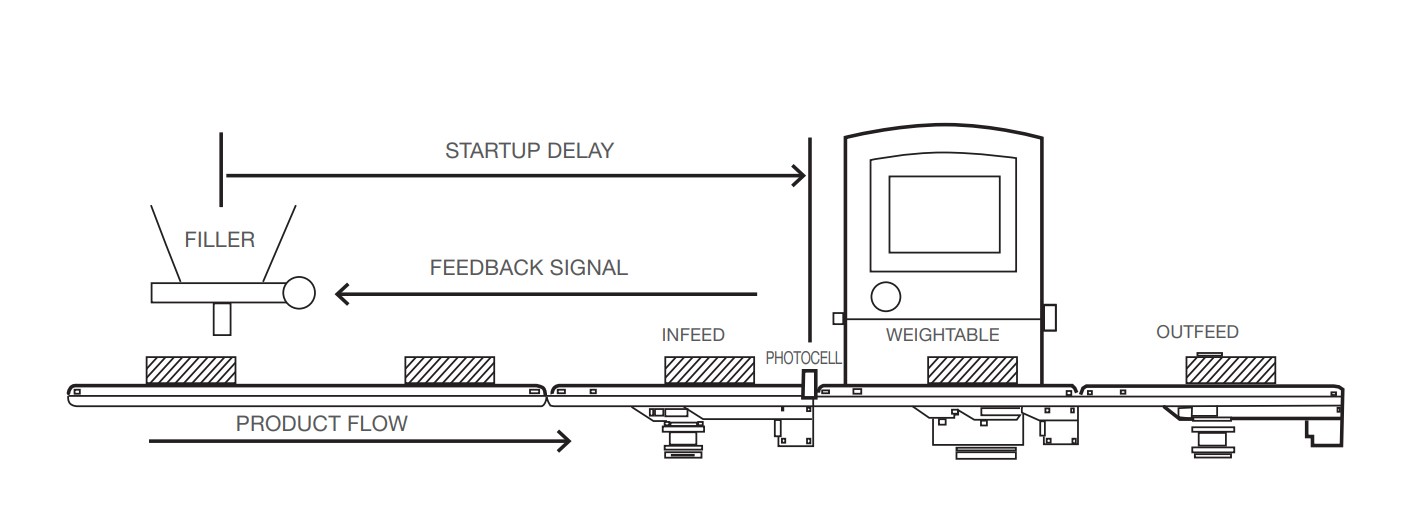

Ngexesha lokuvelisa, ubunzima obuqhelekileyo bulinganiswa ngaphezu kwenani elimiselweyo leemveliso.Ukutenxa kobunzima ekujoliswe kuko kubalwa kwaye inyathelo lithatyathwe xa lifuneka ngophawu lolungiso lwempendulo kwisithako esisuka kwi-checkweigher.Ukulibaziseka kusetyenziselwa ukuphepha ukulungiswa okugqithisileyo xa isigcwalisi sikwisigaba sokuqala okanye emva kokutshintshwa kwemveliso.

Umphathi weplanti unokusebenzisa isoftware ekhethiweyo yokutshekisha ukondla idatha kwi-filler.Kungenjalo, idatha ye-checkweigher ingathunyelwa kwisoftware yokuvelisa ephucukileyo enokuthi iprosesa isebenzise ukulawula iiparamitha zokuvelisa.

Liliphi ixesha elifanelekileyo lokongeza umsebenzi wempendulo?

Abaphathi bezityalo kunye namaqumrhu ahlala ejonge inkcitho eyinkunzi kwaye ebala imbuyekezo.Ukongeza olu hlobo lomsebenzi kumsebenzi wemveliso unokubuyisela imbuyekezo ngexesha elifanelekileyo, ngenxa yeenzuzo zokulondoloza iindleko ezichazwe ngaphambili.

Ixesha elifanelekileyo lokuphonononga iinketho kuxa umgca omtsha wemveliso uyilwa okanye xa iifayili kunye ne-checkweighers zihlaziywa ukusebenza kakuhle.Kusenokuba kufanelekile xa kusenziwa isigqibo sokuba kukho ipesenti ephezulu yenkunkuma yesithako ebiza imali eninzi ngenxa yokuzaliswa ngokugqithisileyo, okanye ukuba ukungazaliswa kakuhle rhoqo kubeka inkampani emngciphekweni wesenzo solawulo okanye izikhalazo zabathengi.

Iingqwalaselo ezongezelelweyo zokujonga ubungakanani obuphezulu

Kukwabalulekile ukuba ungahoyi ezinye izikhokelo zomgangatho wokutshekishwa osebenza kakuhle.Ezi ziquka:

• Khangela isilinganisi kufutshane nesizaliseko

• Gcina isikali sakho sikwimeko entle

• Qinisekisa ukuba isignali yengxelo idityaniswe ngokufanelekileyo nesigcwalisi

• Gcina unikezelo olululo (isithuba, ukuphakama) kwemveliso kwisikali sokutshekisha

Funda nzulu

Inzuzo yezemali yenkampani nganye inokwahluka kakhulu ngokuxhomekeke kwisixa kunye neendleko zokunikezelwa kwemveliso ezinokuncitshiswa kakhulu ngedatha yexesha langempela elixabisekileyo.

If you would like to get more information on how we can assist you with your product inspection requirements, please contact us at fanchitech@outlook.com.

Ixesha lokuposa: Jun-14-2022