1.1 scenario requirements

Airport scale: an international hub airport, with an average daily passenger flow of 150000 and a peak baggage security check of 8000 pieces per hour.

Original problem:

The resolution of traditional equipment is insufficient (≤ 1.5mm), and it is unable to identify new nano camouflage explosives.

The rate of manual misjudgment is high (about 12%), resulting in more than 20% of the secondary unpacking rate and serious passenger detention.

The equipment maintenance cost is high (the annual maintenance cost is about $500000), and it does not meet the ICAO explosion-proof detection standard updated in 2024.

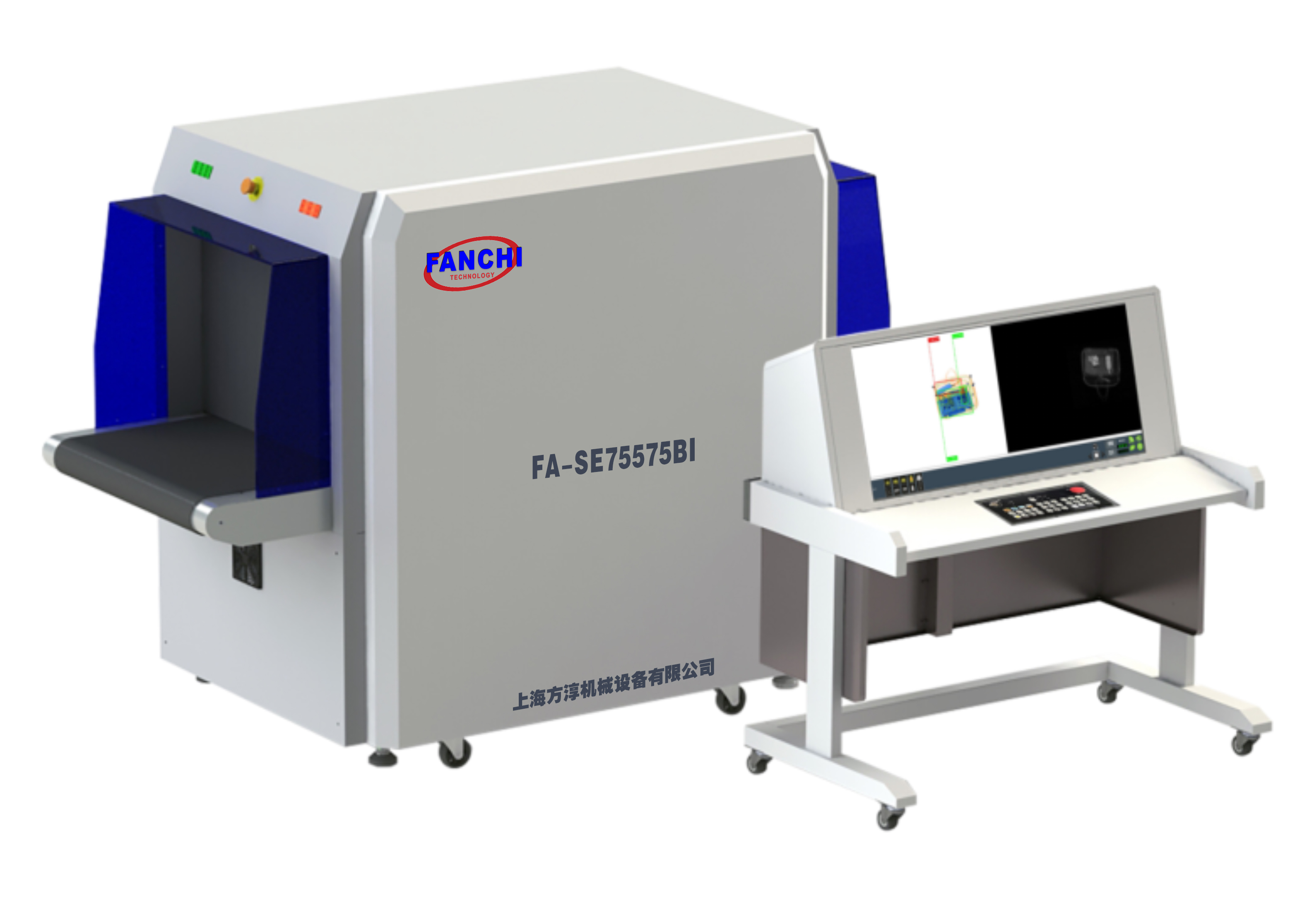

Therefore, it is decided to introduce advanced X-ray security inspection equipment. After multiple evaluations, Shanghai Fangchun mechanical equipment Co., Ltd Security inspection equipment was selected for its high resolution and intelligent operation.

1.2 upgrade objectives

Achieve 100% contactless security inspection and meet the new international aviation safety regulations (ICAO 2024-07).

Reduce the false alarm rate to ≤ 3%, and reduce the secondary unpacking rate to less than 5%.

Support multimodal data linkage (real-time matching of baggage, face and flight information).

2、 Technical parameters and innovation points of equipment

2.1 core performance of the equipment

Parameters indicators

Resolution 0.05mm

Detection speed 600 pieces/hour

AI recognition algorithm

Energy consumption 15kw/H

2.2 technological breakthroughs

Quantum energy spectrum analysis technology: identification of organic/inorganic substances by X-ray energy spectrum fingerprint

Edge computing node: deploy AI model locally (delay<50ms) to avoid the risk of cloud transmission.

Self cleaning conveyor belt: nano coating reduces foreign matter sticking, and the maintenance cycle is extended to 3000 hours.

3、 Deployment plan and implementation details

3.1 system architecture

Baggage sorting → machine scanning → real time AI determination (dangerous/non dangerous)

↳ dangerous goods → audible and visual alarm+automatic sorting to the isolation area

↳ non dangerous goods → synchronize data to the customs/Aviation Department System (bound with passenger biological information)

4、 Application effect and data validation

4.1 improvement of safety efficiency

Indicators before upgrading rate of change after upgrading

The detection rate of dangerous goods is 82% 99.7% ↑ 21.6%

False positive rate 12% 2.3% ↓ 80.8%

The average security check time is 8 seconds/piece 3.2 seconds/piece ↓ 60%

4.2 operation cost optimization

Labor cost: reduce the re inspection personnel by 50% (save $1.2 million annually).

Customs clearance efficiency: the average waiting time of passengers decreased from 45 minutes to 12 minutes (satisfaction increased to 98%).

5、 Customer testimony and industry impact

Evaluation of safety director of an international airport:

This device not only solves the “fuzzy scanning” pain point of traditional equipment, but also seamlessly connects with the customs system, allowing us to complete security check, customs declaration and baggage tracking simultaneously in one scan. With the help of this system, we intercepted three new liquid bomb threats, which proved the foresight of the technology. “

Post time: Feb-24-2025