Fanchi X-ray Inspection System Designed for Fishery Industry

Product Highlights

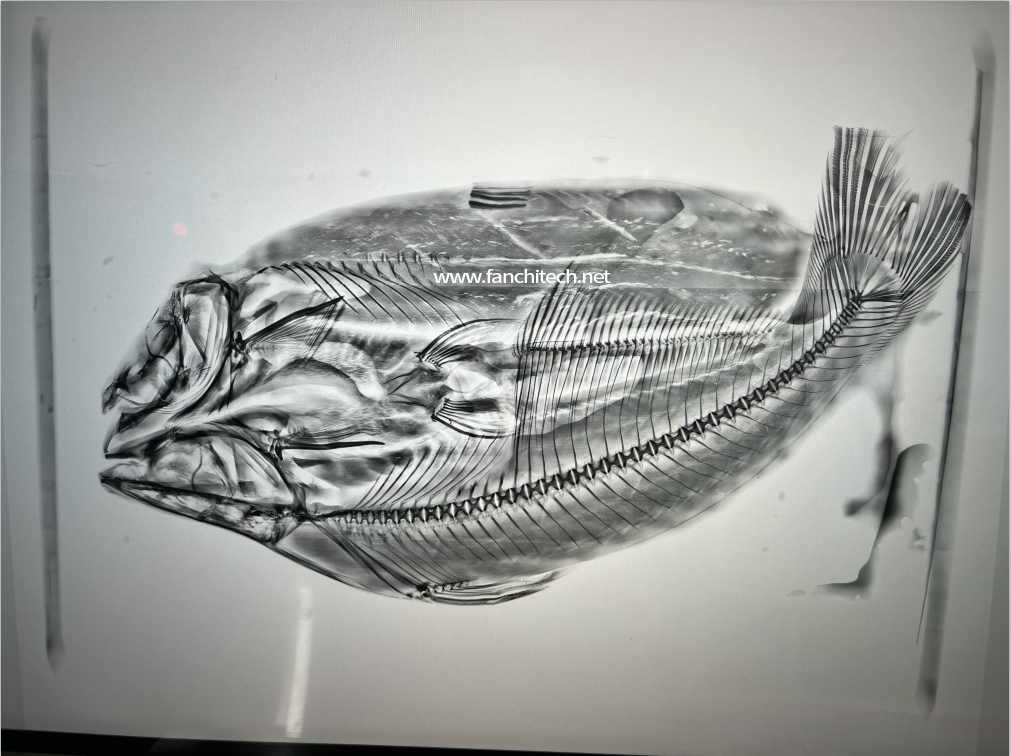

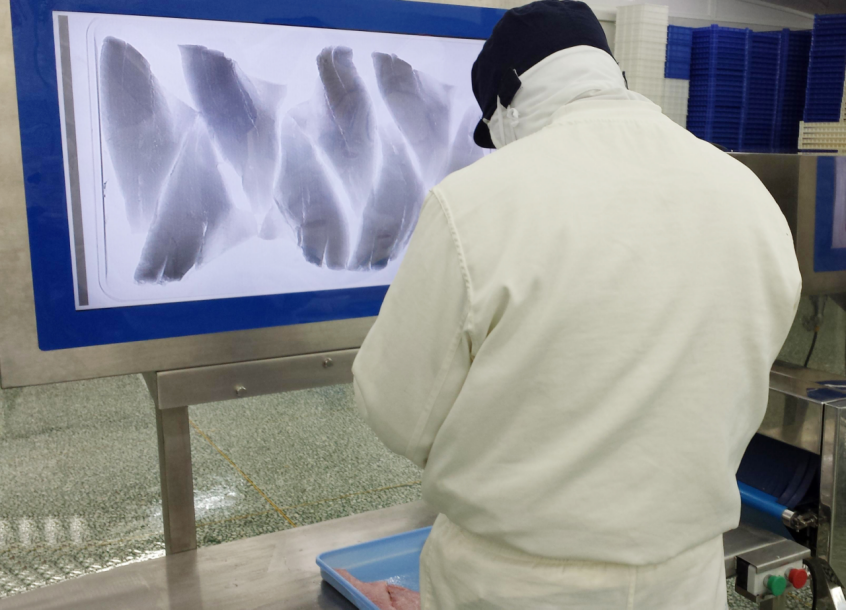

1. X-ray inspection specially for fishery industry

2. Auto parameter setting by intelligent product learning

3. Detects high density materials like metal, ceramic, stone, hard rubber, fish bone, hard shell, etc

4. Easy operation with auto-learn and clearly arranged functions on 17” touch screen

5. Fanchi advanced algorithm software for instant analysis and detection with high accuracy and reliability

6. Quick release conveyor belt for easy cleaning and maintenance

7. Real time detection with colored contamination analysis

8. Masking functions available

9. Auto-storing of inspection data with time and date stamp

10. User-friendly menus for easy operation

11. USB and Ethernet ports available

12. Built-in remote maintenance and service by Fanchi engineer

13.CE approval

Functions and Scope of Delivery

It is particularly suitable for packaged food or non-food products, like in boxes, plastic packaging and even metal foils or metal cans. Undesirable contaminants such as metal, stone, ceramic or plastic with high density and fish bone can be detected. Multi-level user security Certified test cards come together with the machine

Hygienic Design and Lead-free Curtains

The hygienic design allows easy cleaning and maintenance without any additional tools. Thus, the Fanchi FA-XIS is especially suitable for all industries that have to ensure effective hygienic standard(also available with IP66). Lead-free curtains help to prevent leakage of x rays from the machine cabinet

Lowest cost of ownership

Fanchi FA-XIS X-ray Inspection Systems are designed to provide great detection performance with low power consumption. Coupled with intelligent cooling systems to prolong X-ray tube life, sealed x-ray generators with non-circulating oil, and maintenance free rollers, all these lead to an overall low cost of ownership.

Key Components

1. US VJT X-ray Generator

2. Finnish DT X-ray Detector/Receiver

3. Danish Danfoss frequency converter

4. German Pfannenberg industrial air conditioner

5. French Schneider electric unit

6. US Interoll electric roller conveying system

7.Taiwanese Advantech industrial computer and IEI touch screen

Technical Specifications

| Model | FA-XIS4016F |

| Stainless Steel 304 (Ball/Wire) | Ball: 0.3mm; Wire: 0.2x2mm |

| Ceramic Ball | 1.0mm |

| Glass Ball | 1.0mm |

| Fish Bone | 0.2x2mm |

| Tunnel Size (WxH mm) | 400x160mm |

| Conveyor Speed | 5-20m/min |

| Conveyor Belt Material | FDA approved food grade PU belt(light blue color) |

| Max. Product Weight | 10kg |

| X-ray Source | Single beam x-ray generator with max. 80Kv(350W), variable in voltage+current |

| X-ray Sensor | High-definition X-ray Sensor up to 0.2mm |

| Safety | X-ray protective curtains(lead-free)+quick detachable, magnetic safety switches at cabinet doors and tunnel hatches, emergency stop buttons, x-ray off key switch, etc. |

| Cooling | Industrial air conditioner(Germany Pfannenberg) |

| Material of Construction | 304 Brushed stainless steel |

| Available Rejecting Mode | Stop Mode and Manual View |

| Compressed Air Supply | N/A |

| Product Memory | 100 different product set-ups |

| Display | 17” color-TFT Touch Screen(operation panel)+1 x 43” HD Monitor |

| Temperature Range | 0 to 40° C (14 to 104° F) |

| Humidity | 0 to 95% Relative Humidity (Non-condensing) |

| IP Rating | IP66 |

| Supply Voltages | AC 220V single phase, 50/60Hz adaptive, 2kva |

| Software Language | English(Spanish/French/Russian, etc optional) |

| Data Transfer | Ethernet for remote support via internet, USB for external keyboard/mouse/memory stick |

| Certificates | CE/ISO9001/ISO14001/FDA |

Note:

1. The metal detector head size can be customized as per clients' product size;

2. The sensitivity mentioned above namely is the result of sensitivity by detecting only the test sample on the belt.

3. The sensitivity would be affected according to the products being detected, working condition and also the different positions the metal mixed with.