Fanchi-tech Heavy Duty Combo Metal Detector and Checkweigher

Introduction&Application

Fanchi-tech's integrated Combination Systems are the ideal way to inspect and weigh all in one machine, with the option of a system combining metal detection capabilities along with dynamic checkweighing. The ability to save space is an obvious advantage for a factory where room is a premium, as combining the functions can help save up to around 25% with this Combination System's footprint versus the equivalent if two separate machines were to be installed.

With Combination Systems being able to check the product's weight, they are perfect for checking food in its finished form, such as packaged food to go and convenience foods that is about to be shipped to the retailer. With a Combination System, customers have the reassurance of a robust Critical Control Point (CCP), as it is designed to highlight any detection and weight issues, helping improve quality of production output and simplifying processes.

Product Highlights

1.Combined checkweigher and metal detector with individual HMI, for packages up to 50kg.

2.Detector head by hard-fill technology provides stable and high metal sensitivity.

3.Excellent processing and weighing by FPGA hardware filter with intelligent algorithms.

4.Stronger anti-interference against metal detection by multiple filtering and X - R orthogonal decomposition algorithm,

5.Automatic parameter setting by intelligent product sampling.

6.Ultra-fast dynamic weight tracking and automatic compensation technology to effectively improve the weighing stability.

7.Easy operation by friendly touch screen HMI.

8.Storage of 100 product programs.

9.High capacity operation statistic record with USB data output.

10.High precision structural components and stainless steel 304 frame by CNC tooling.

Key Components

● German HBM fast load cell

● German SEW motor

● Danish Danfoss frequency converter

● Japanese Omron optic sensors

● French Schneider electric unit

● US Gates synchronous belt

● Food grade conveyor belt

● Weinview industrial touch screen display with USB data output

● Heavy duty pusher rejector with Japanese SMC pneumatic unit on roller conveyor

Technical Specification

|

Model |

FA-CMC500 |

FA-CMC600 |

|

Detecting Range |

100g~25kg |

100g~50kg |

|

Scale Interval |

1g |

1g |

|

Detecting Accuracy |

±10g |

±20g |

|

Detecting Speed |

50pcs/min |

35pcs/min |

|

Weigher Size(W*L mm) |

500x1500 |

600x1500/1800 |

|

Metal Detector Head Size |

600x350mm |

|

|

Metal Detector Sensitivity |

Fe≥2.0, NFe≥2.5, SUS304≥3.0 |

|

|

Material of Construction |

Stainless Steel 304 |

|

|

Belt Type |

PU Anti Static |

|

|

Line Height Options |

700,750,800,850,900,950mm +/- 50mm(can be customized) |

|

|

Operation Screen |

7-inch LCD Touch Screen |

|

|

Memory |

100 kinds |

|

|

Weigh Sensor |

HBM high accuracy load cell |

|

|

Rejector |

Heavy Pusher Rejector |

|

|

Air Supply |

5 to 8 Bar (10mm Outside Dia) 72-116 PSI |

|

|

Operating Temperatures |

0-40℃ |

|

|

Self-diagnosis |

Zero error, photosensor error, setting error, products too close error. |

|

|

Other Standard Accessories |

Windshield cover(colorless and clear), photo sensor; |

|

|

Power Supply |

AC220V, 1phase, 50/60Hz, 750w |

|

|

Data Retrieval |

Via USB(standard), Ethernet is optional |

|

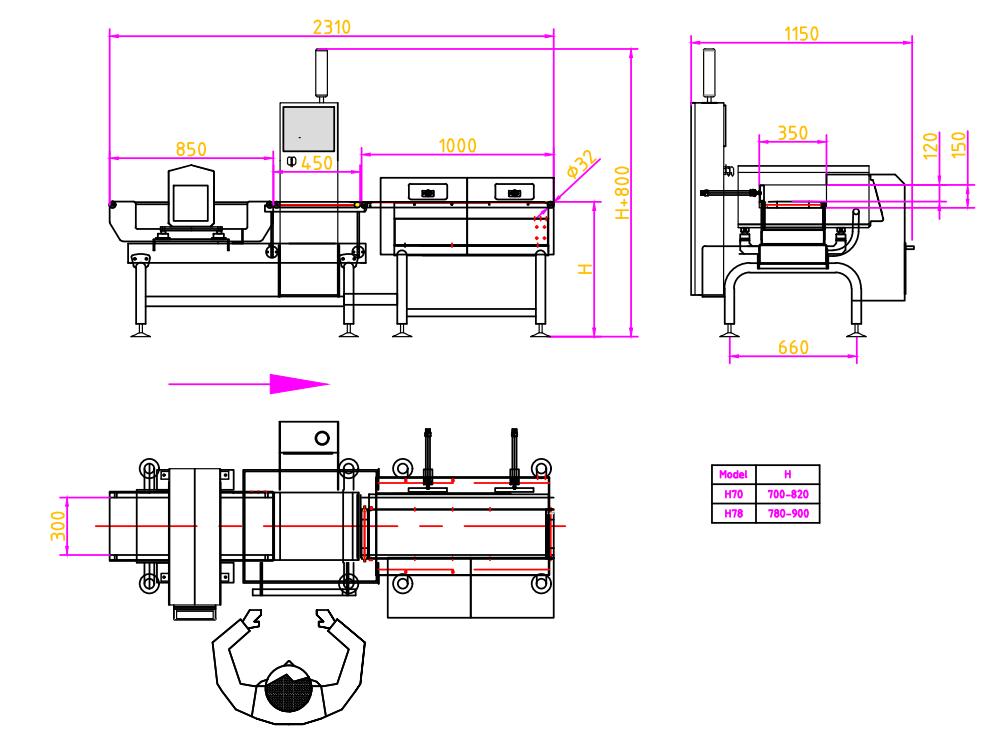

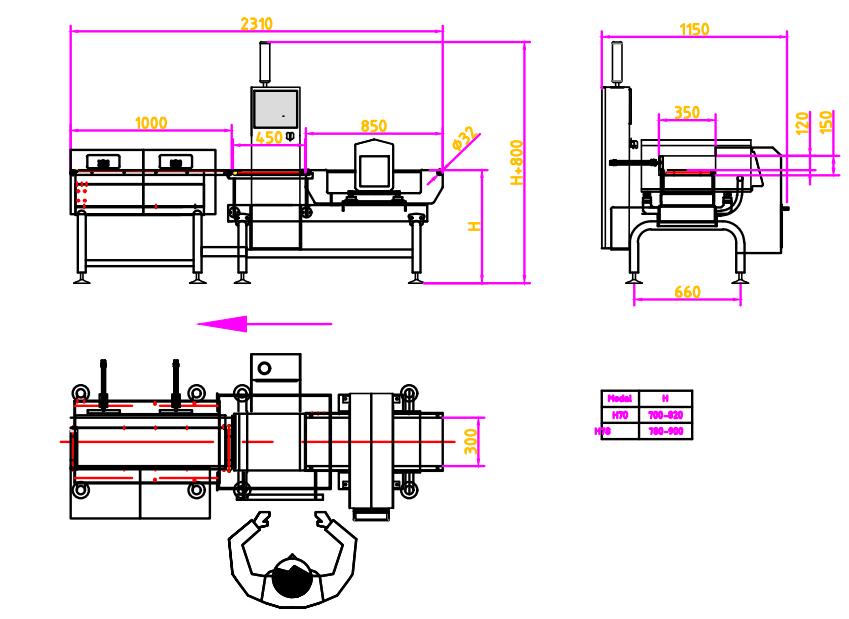

Size Layout